Stamping die has entered a golden period of rapid development

In recent years, mold industry to speed up the adjustment of product structure, to large, sophisticated, complex, long-life mold as the pace of development of high technology content of the mold is higher than the overall growth rate representative of the industry, accounting for about 35% of the total die.

China's total current production of stamping parts processing die in the world, has been ranked in the forefront, and began gradually changed from the mold importer mold exporters. Our more than 30,000 existing mold manufacturing enterprises, employing approximately 100 million people, 2012 annual sales of 124 billion yuan, sales booming, yield, quality and level has been further improved, especially the development of the automotive industry and IT manufacturing pulling the mold quality improvement, excellent mold manufacturing equipment to enhance the level of mold technology has provided a guarantee. China's mold industry is experiencing a "golden stage of development", the period ahead will continue to maintain sustained and rapid growth.

From the industry structure, the rapid development of private enterprises, state-owned enterprises vitality, market-oriented professional mold manufacturers number and capacity increased rapidly, to adapt the production characteristics of the mold industry gathering mold stamping parts processing production parks have been developed, such as mold industry owe Midwest developed regions have greater progress.

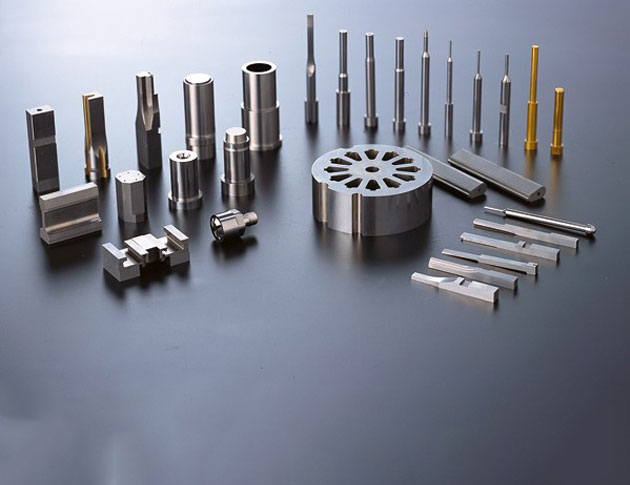

Some die stamping parts processing enterprises multi-position progressive die precision has reached 2 microns, life expectancy up to 300 million times more punch, multi-position progressive die individual enterprises can already use 2500 times / min high-speed punch, precision up to 1 micron. Capable of producing 43 inches big screen TV, 65 inches rear projection TV Molded mold, 10 kg capacity washing machine full set of plastic molds and car bumpers, instrument panels and other large overall plastic mold.

Precision plastic mold stamping process capable of producing plastic molds for cameras and mobile phones, multi-cavity small module gear.